Why choose our Cellulosic Technology

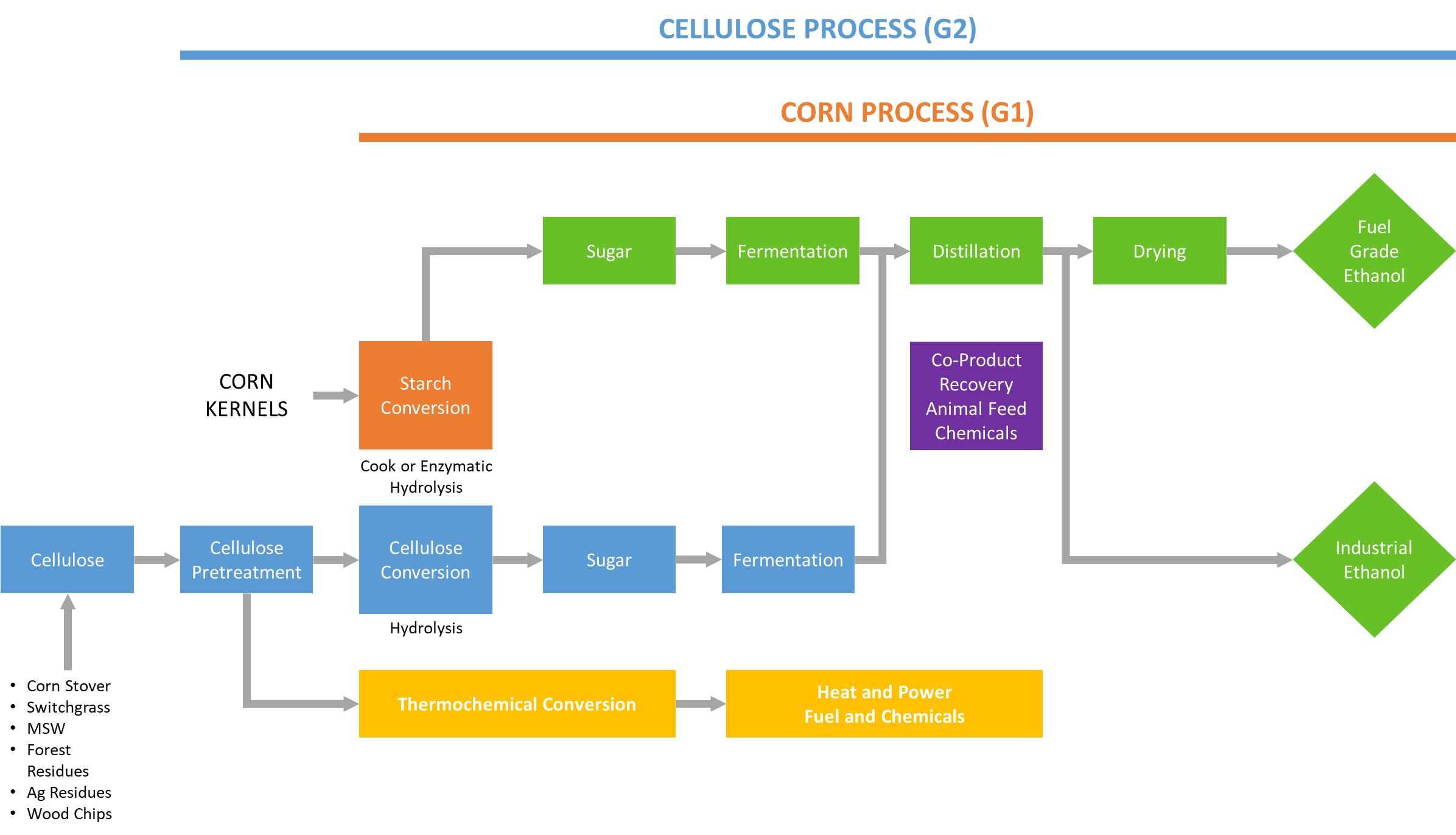

Biofuel produced from lignocellulosic biomass, so-called second-generation (G2) bioethanol, shows environmental advantages in comparison to first-generation (G1) bioethanol from starch or sugar.

However the conversion of lignocellulosic biomass to ethanol is more challenging due to the complex structure of the plant cell wall. The physical and chemical barriers caused by the close association of the main compo-nents of lignocellulosic biomass hinder the hydrolysis of cellulose and hemicellu-lose to fermentable sugars. Pretreatment is needed to alter the structural and chemical composition of lignocellulosic biomass to facilitate the rapid and efficient hydrolysis of carbohydrate to fermentable sugars.

Using the latest advances in this field, STC will offer to their clients a state of the art technology for the production of second generation Cellulosic Ethanol. Our R&D Department along with our partners will ensure the most effiecient process in order to obtain ethanol from the cellulosic available in forrest residues.

The key is in the pretreatment stage, the variety in physiochemical characteristics of cellulosic biomass reveals the need for pretreatment technologies to help in the rapid and efficient conversion of carbohydrate polymers into fermentable sugars.

Our suitable pretreatment method, enhance the enzymatic hydrolysis of biomass because of the crystalline structure of cellulose and the complex structure of lignin and hemicellulose, improving the sugar yield, avoiding the degradation of sugars derived from hemicellulose and minimize the formation of inhibitors for subsequent fermentation steps.

After the pretreatment, the sugar is fermented to obtain ethanol. Efluent from the fermenters, containing ethanol and other components, is fed to a separtion unit, filters and then dried, where pure fuel-grade ethanol is obtained as a main product.

Our process significally minimize heat and power requirements to be cost effective in operation.

For larger projects, where ours G1 and G2 technologies are used to obtain ethanol from diferent sources (e.g. corn and eucalyptus). After the fermetation stage, effluents from both porduction lines containing crude ethanol, can be mixed, to be separated and filtered together downstream to reduce the CAPEX of the project.

A general schematics for G1 and G2 technologies is show below as reference, notice that pretreatment section used in G2 is thr only stage of the process that differs from G1 technology, that's why our integrated process will reduce the CAPEX of our clients projects, using same line of distillation and drying for the production of the ethanol. Since, ethanol will have the same characteristics, material balance will be enought to dertemine the amount of ethanol obtained from biomass (G2 Technology).

Nevertheless, if customer require it, standalone development of G2 technology can be done without any inconvenience, under the same standards of quality, performance and costs.